| So i just got my 120k kit, along with a UR crank pully and an H.I. overdrive water pump pully (thanks bernie). The motor i put it on was this I got out of my $1,200 crashed 92 TT that i found a couple years back with only 63K on it. Well when i threw it in i checked the compression hot and it had 150psi all around. I dont think ive put more than 5k on the motor. So i check the compression now and #1

#3

#5

#2

#4

#6

Super depressing, even though these were done on a cold motor, those numbers are bad. #5 is murked for sure. Its time for a rebuild.

I threw on the 120k kit anyway.

It was all oem. all the usual stuff. Timing Belt

Timing Belt Tensioner

Water Pump

Water Pump Gasket

Thermostat

Coolant Bypass Hoses x2

Variable Timing Control Springs x2

Variable Timing Control O-rings x2

Camshaft Seals x4

Crankshaft Seal x1

Crankshaft Sprocket Spacer Rear

Drive Belts(3 Included)

Idler Pulleys, Timing Belt x2

Idler Pulley Studs x2

Ramzey studs Fan and radiator out.

Belts and crank pully off.

the waterpump was leaking back when this motor was in the other chassis and i was in a bind one day and didnt have any allen wrenches with me so i just took off the lower cover by its self. i took a bit of perswading but it came off. I just never put it back, stupid i know.

Covers off.

Belt /tensioner off.

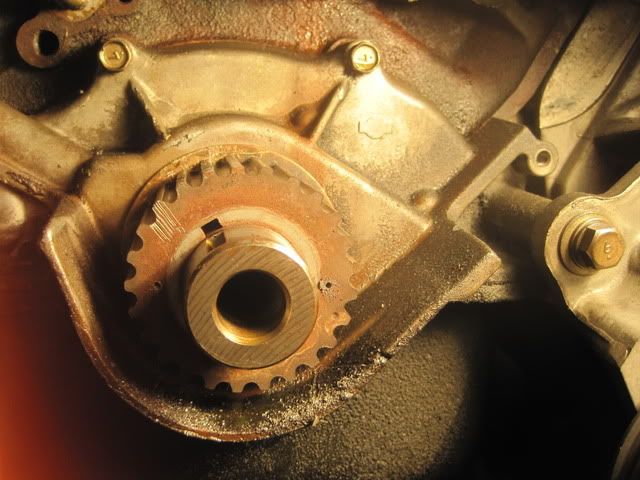

My mission with removing this dam crank gear. First i tried pulling it.

Looks like it shoulda worked no? Well just about when i was ready to break my 19mm gearwrench from turning so hard, I pulled the threads out of one of the holes, which sent my forehead flying straight into the the TB linkage. That felt nice... I said F#$K the proper way and cut the crap off.

Put a nice little mark on the crank and oil pump too.

Dirty motor.

Less dirty motor. Still had to clean the old gasket off.

Kinda forgot about taking pics for awhile. But at this point i cleaned up all the mating surfaces, installed all the seals, installed the water pump, new crank gear, rear washer (valley toward belt), Ramzy idler studs with blue locktite, new idler pullys, backing plates, Intake and exhaust cam grears, VTC springs/Orings, all torqued per FSM. I reused my old water pump pipes, i didnt want to but i didnt have the cash to buy new ones this week.

Belt and tensioner installed. The clamps and piece of wood in the crank gear makes this job cake to do.

4mm overnight !!!

Tensioner "bolt" removal proof!

Timing Covers installed. href="http://s376.photobucket.com/albums/oo202/campbeln2007/?action=view¤t=IMG_1803.jpg" target="_blank"> Done!

She started up without a hitch, had a lifter tick for a bit and smoothed out. She is so quite now. Its nice. Im going to recheck the compression when the motors warm in a couple days to see what kind of shape im really in. But i expect to have to rebuild it soon. It will be a cool learning experience.

|